trolley for mold replacement

HOME / TROLLEY FOR MOLD REPLACEMENT

Following the new market needs, in recent years we have developed a fast, safe and totally electric mold transport system.

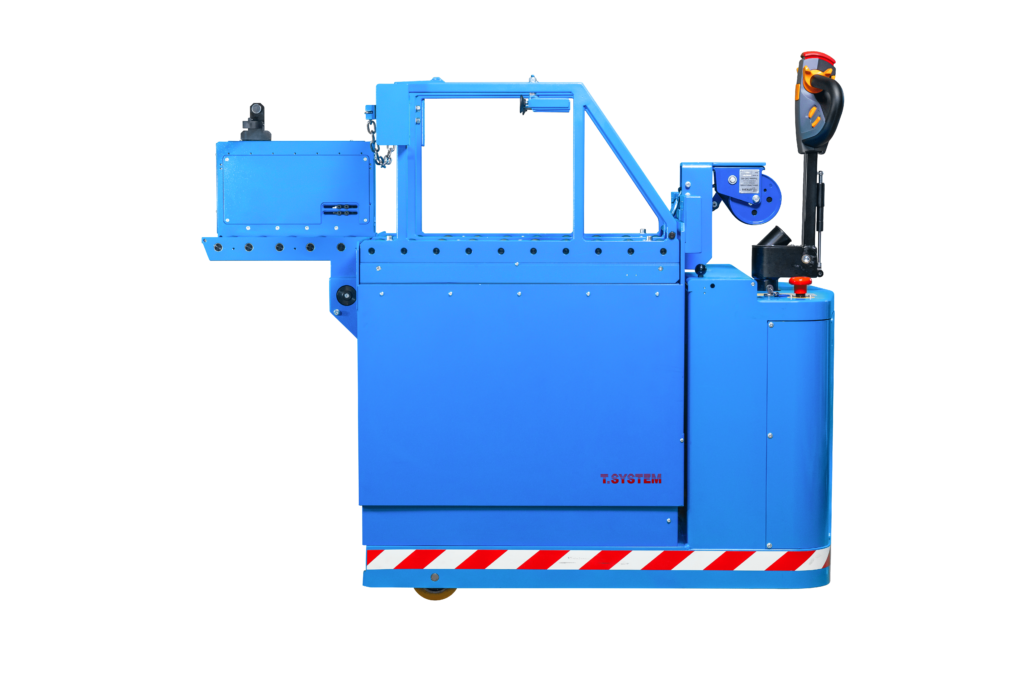

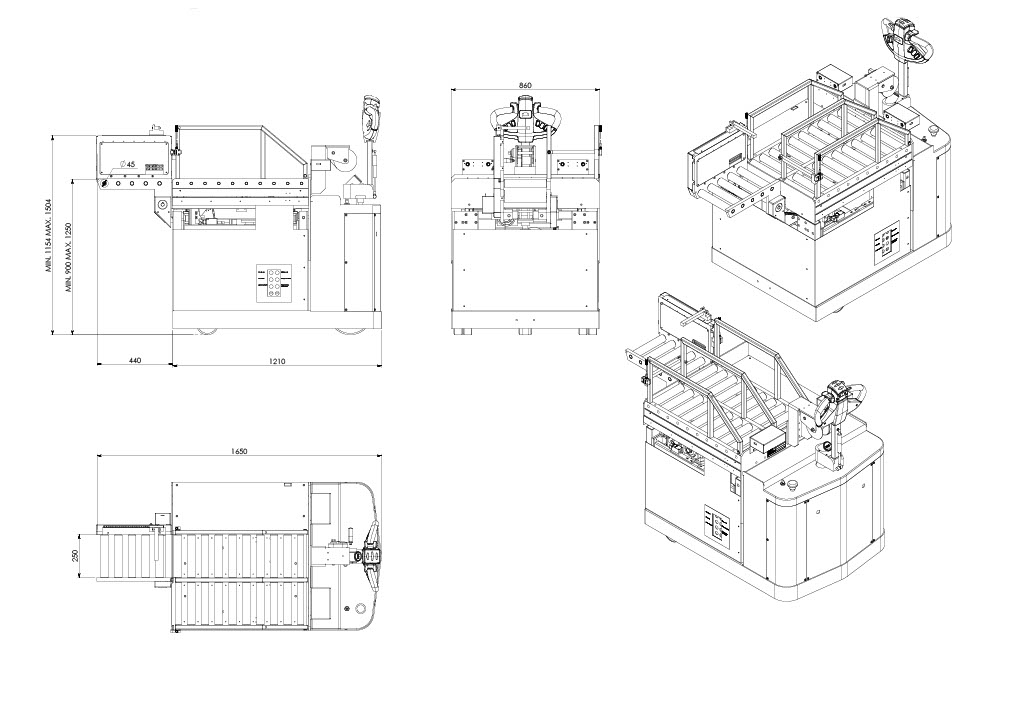

DL1080

Trolley for mold changing moduls on horizontal injection rubber moldings mod. DL1080 with transfer system and auxiliary movements both driven by an only strong energy source represented by a high-performance battery rechargeable in 7 hours. It has a transfer speed and a very low speed for positioning. It is designed stable with three points of support on the floor using the easy and ergonomic rudder guide while retaining a very small total length that allows it to be positioned even in very narrow spaces in slow mode with straight rudder. All commands are located on the rudder.

To adapt to the height of the single press, the trolley has an electromechanical vertical handling system.

For the extraction and introduction of the mold from the press, the trolley has a motorized roller conveyor jutting from the back, while the exchange between the replaced mold and the new mold is through a double roller conveyor moving sideways with electromechanical motorization.

For the first mold detachment operation from the support on the press, the trolley has a manual belt winch that avoids the operator any non ergonomic operation.

For safety purposes, the trolley has a series of practical measures such as:

- • settable logic and safety sensors in the control circuit;

- • side barriers for containment and possible stamping of the mould;

- • safety bar monitored against accidental spillage of the mould that can be positioned dually;

- • adaptive press release accessories for preventing reaction forces;

- • EC fixed guards to protect the dangerous points for the movement of the equipment;

- • laser sensors to check the mold position;

- • monitoring and automatic intervention devices in case of abnormal wear during lifting;

- • emergency stop button and key switch for safe general shutdown;

- • precise trim conditions to be fulfilled for safe transfer at normal speed.

For diagnostic purposes, the DL1080 trolley has a display for information on the transfer parameters and battery charge and a chromatic panel with light indicators for monitoring auxiliary functions and any alarms.