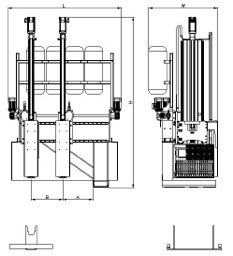

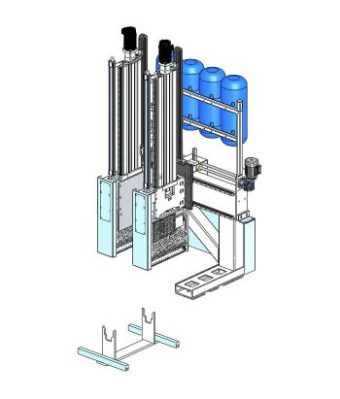

300 2DBE

Brushing unit built on robber molding injection machines having 300 ton molding loan. No.2 axis, one with injection plate. Fixed and mobile structure in steel carpentry produced on the machine tool. Axis ascent and descent driven by linear ball guides and motorized through linear actuators. Brushes rotation electrically motorized with toothed belt transmission integrated in the structure. Horizontal movement driven by linear ball guides through electric motor. Optional blowing system.

| Tecnical data | ||

| Numero di assi/ Number of axis / Achsen Nr. | 2 | |

| Numero spazzole/ Number of brush/ BÜrsten Nr | 2 | |

| Lunghezza spazzole/ Brush length/ Bürstenlänge | mm | 525 |

| Diametro spazzole/Brush diameter/Bürstendurchmesser | mm | 190 |

| Useful stroke adjustment brush A min | mm | 114 |

| Useful stroke adjustment brush A MAX | mm | 644 |

| Useful stroke adjustment brush B min | mm | 210 |

| Useful stroke adjustment brush B MAX | mm | 720 |

| Min: lunghezza stampo/mold width/ Mindestlänge Form | mm | 340 |

| Max: lunghezza stampo/mold width/ Länge Form | mm | 900 |

| Useful vertical stroke brushes | mm | 1100 |

| Spessore setole/ Bristle thickness/ Borstendichkle | mm | 0,4-0,6-0,8 |

| Motorized linear actuator for brush’s vertical | movement 1 e 2 | |

| Potenza nominale/ Nominal power/Nennleistung | kW | 1,451 |

| Corrente nominale / Nominal current/ Nennstorm | A | 2,84 |

| Velcoità nominale /Rated speed/ Nenndrehzahl | Rpm | 3000 |

| Brushes’ electrospindles | ||

| Potenza nominale/ Nominal power/Nennleistung | kW | 2 x 0,75 |

| Corrente nominale / Nominal current/ Nennstorm | A | 4,3/2,6 |

| Velcoità nominale /Rated speed/ Nenndrehzahl | Rpm | 3000 |

| General | ||

| Voltaggio Nominale/ Nominal voltage/ Nennleistung | V | 380 |

| Frequenza/ Frequency/ Frequenz | Hz | 50 |

| Pressione massima/ Max air pressure/ Luftdruck | bar | 6 |

| approximative mass of the brushing unit | kg | 650 |

| Lunghezza/ Lenght machine/ Maschinenlänge (L) | mm | 1570 |

| Larghezza /Width machine/ Maschinenbreite (W) | mm | 960 |

| Altezza /Heigth machine/ Maschinenhohe (H) | mm | 2360 |